Without a clean connector your optics won't work

Without an inspection video microscope, you won't know a dirty or damaged connector.

90% of fiber optic network failures are caused by connectors - 100% Inspection of fiber optic connectors required

Optical connectors in networks are susceptible to dirt and damage. Up to 90% of problems on optical networks are caused by a connector that is in poor condition. When a connector is damaged or dirty, insertion loss increases at the point of connection and reflection increases. This adversely affects signal transmission.

Principle 1: It is not possible to objectively assess the condition of the connector and its cleanliness without a thorough inspection by a video microscope with evaluation according to IEC/IPC standards.

Principle 2: Unconnected connectors must be protected by a cap and cleaned and inspected with a video microscope before each reconnection.

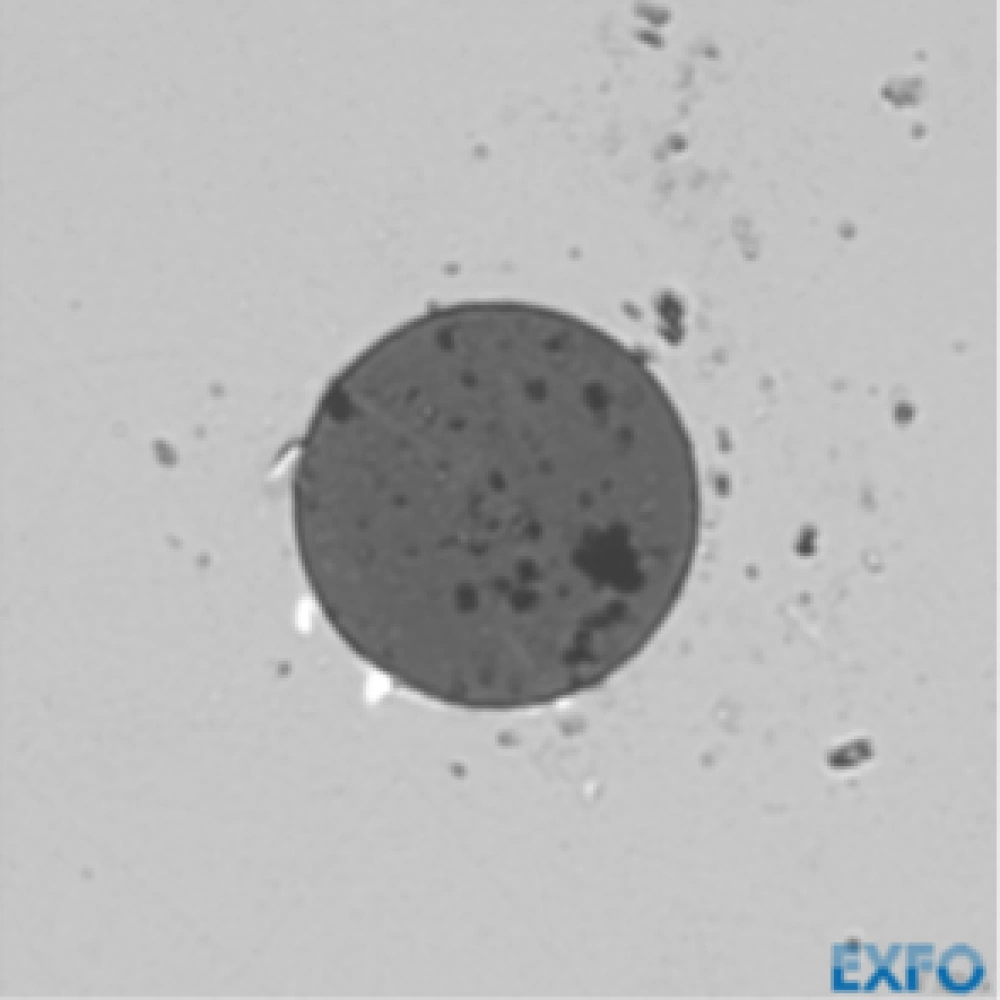

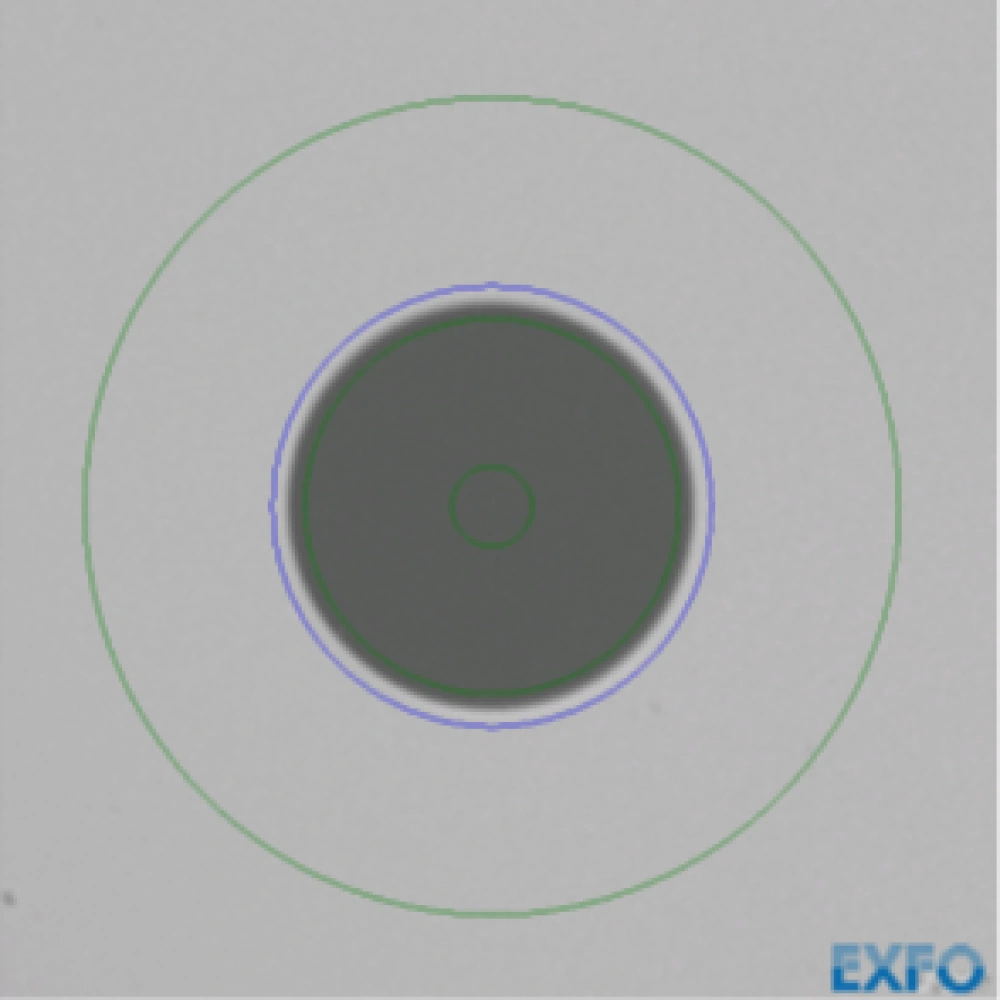

Picture of the connector

Evaluation: dirty connector

Evaluation: clean connector

How to clean connectors properly - Optical cleaning aids

Isopropyl alcohol and paper wipes are most commonly used for cleaning. It is necessary to use pure isopropyl alcohol without additives and lint-free wipes that do not contaminate the fibres. Special cleaning cartridges with cleaning tape, cleaning sticks or pens with cleaning thread are also practical. The advantage of a cleaning pen with a cleaning thread that automatically rewinds and rotates on the connector face is the ease of cleaning optical patch panels in racks

How to clean connectors properly - cleaning aids for optics

Isopropyl alcohol container, lint-free wipes, cleaning pen

For more information, please visit:

https://www.profiber.eu/cz/merici-technika-opticke-komunikace-a-optoelektronika/servisni-pomucky/exfo-inspekcni-videomikroskop-fip-400b-usb/