Technology

The entire software and hardware development and production chain is carried out in the Czech Republic. Processors and other programmable components come exclusively from reputable manufacturers. Thanks to this and other measures, we are able to guarantee the cyber security of our solutions. The creation of a new product is a demanding process requiring the cooperation of a number of specialists in various fields and technologies. To ensure maximum efficiency of the entire development process, we have laboratories equipped with the latest technologies for all stages of development.

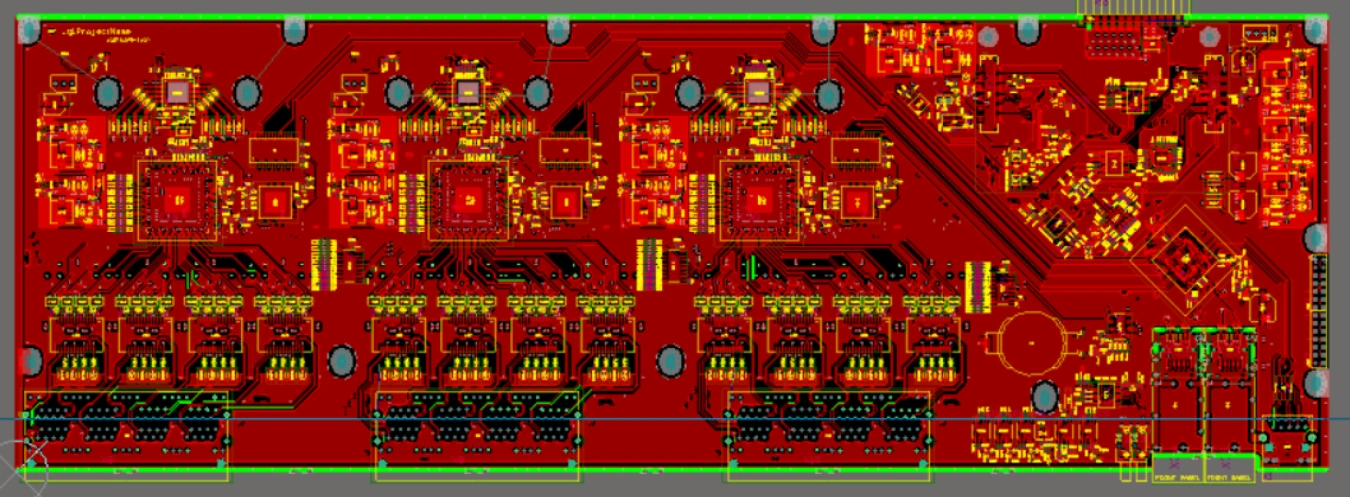

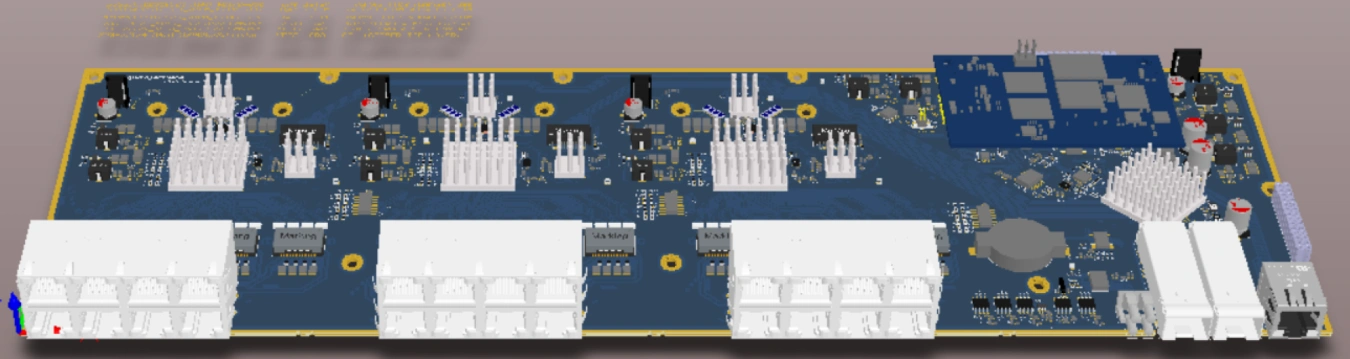

PCB design

A key stage of development is the design of the PCB, which we design using both 2D and 3D tools.

Mechanics

A beautiful and functional cover is half the battle. That's why we don't rely on universal boxes, which are a source of dimensional and functional limitations. Instead, we have developed our own customized aluminium profile

3D printing

Thanks to this new 3D printing technology, we are able to significantly speed up the preparation of final documentation for series production. We also prefer this new technology because it uses environmentally degradable plastic for printing and minimizes the amount of waste produced, thus helping to save the environment.

Climate tests

In the climate chamber, we simulate the operation of the plant over the entire range of operating temperatures and humidity.

Adjustable parameters

- Temperature -42°C up to +190°C

- Humidity 10-98 % RH

Laser marking

Laser marking is an ideal tool for ensuring the long-term durability of labels despite climatic and chemical influences.

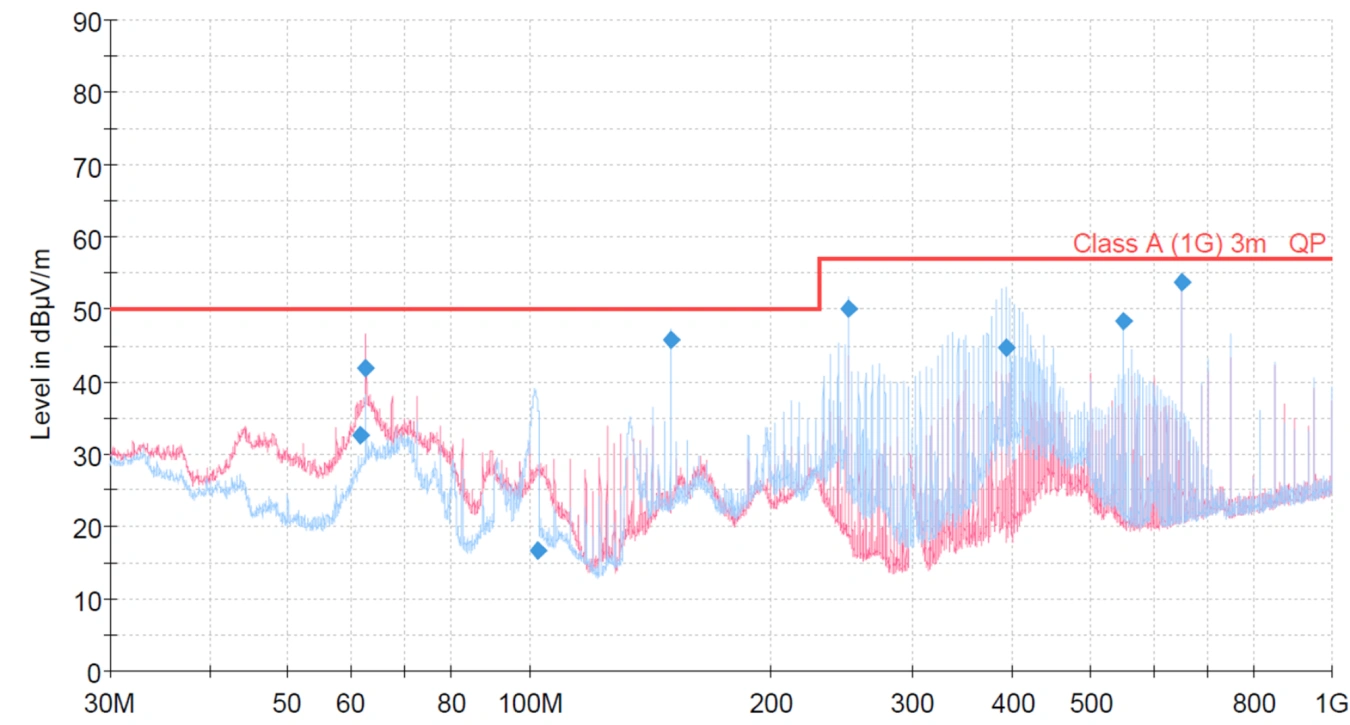

EMC Compatibility Testing

Our measuring stations are equipped with a wide range of measuring instruments for measuring according to standards:

- EN 61000-4-2 - Electrostatic pulses

- EN 61000-4-3 - Electromagnetic fields

- EN 61000-4-4 - bursts

- IEC EN 61000-4-5 - Shock pulses

- IEC EN 61000-4-8 - Magnetic field 50 Hz

- IEC EN 61000-4-9 - Pulsed magnetic fields

- IEC EN 61000-4-11 - Power failures

- IEC 61000-6-4 - Emissions

Surge protectors testing

We test the resistance of our devices on our own 8/20 and 10/350µs wave generators.

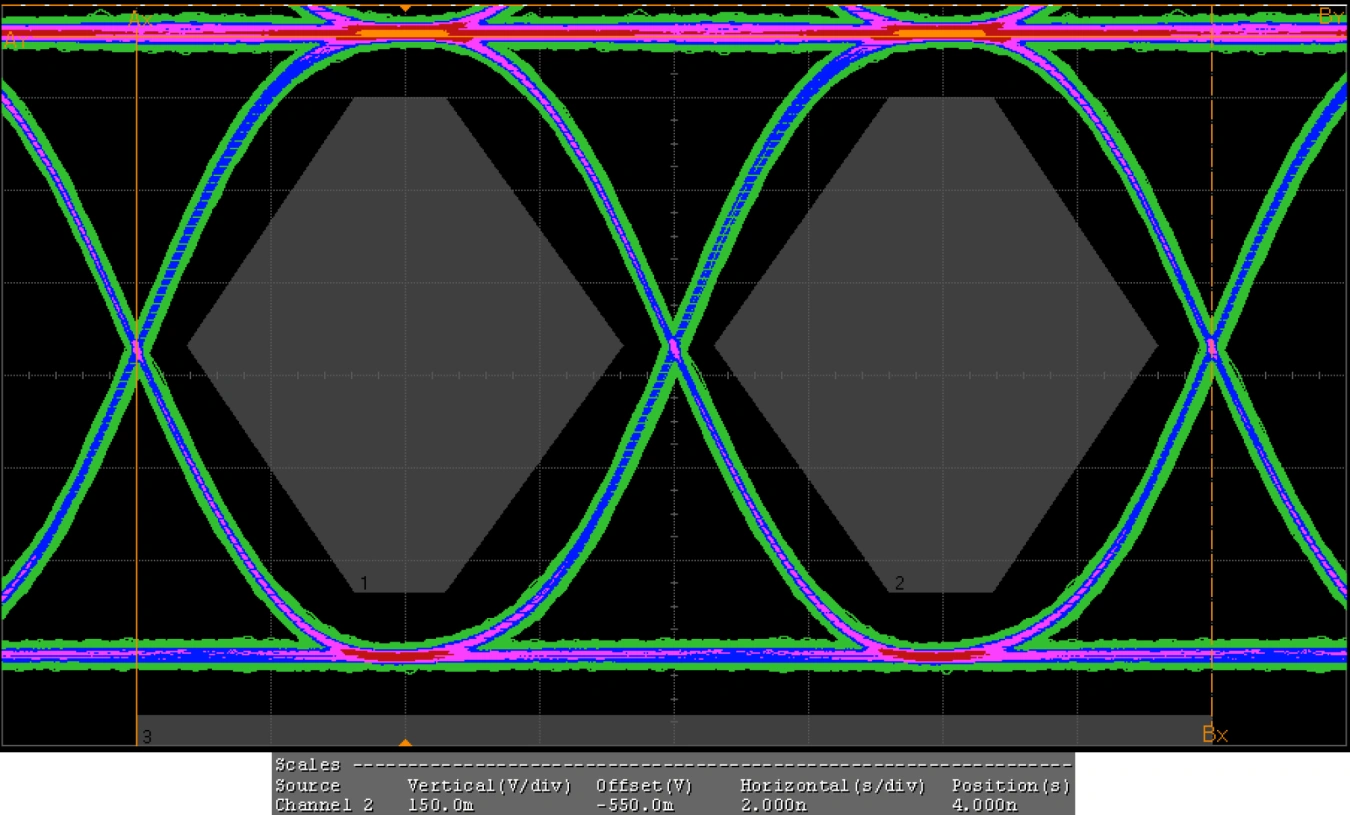

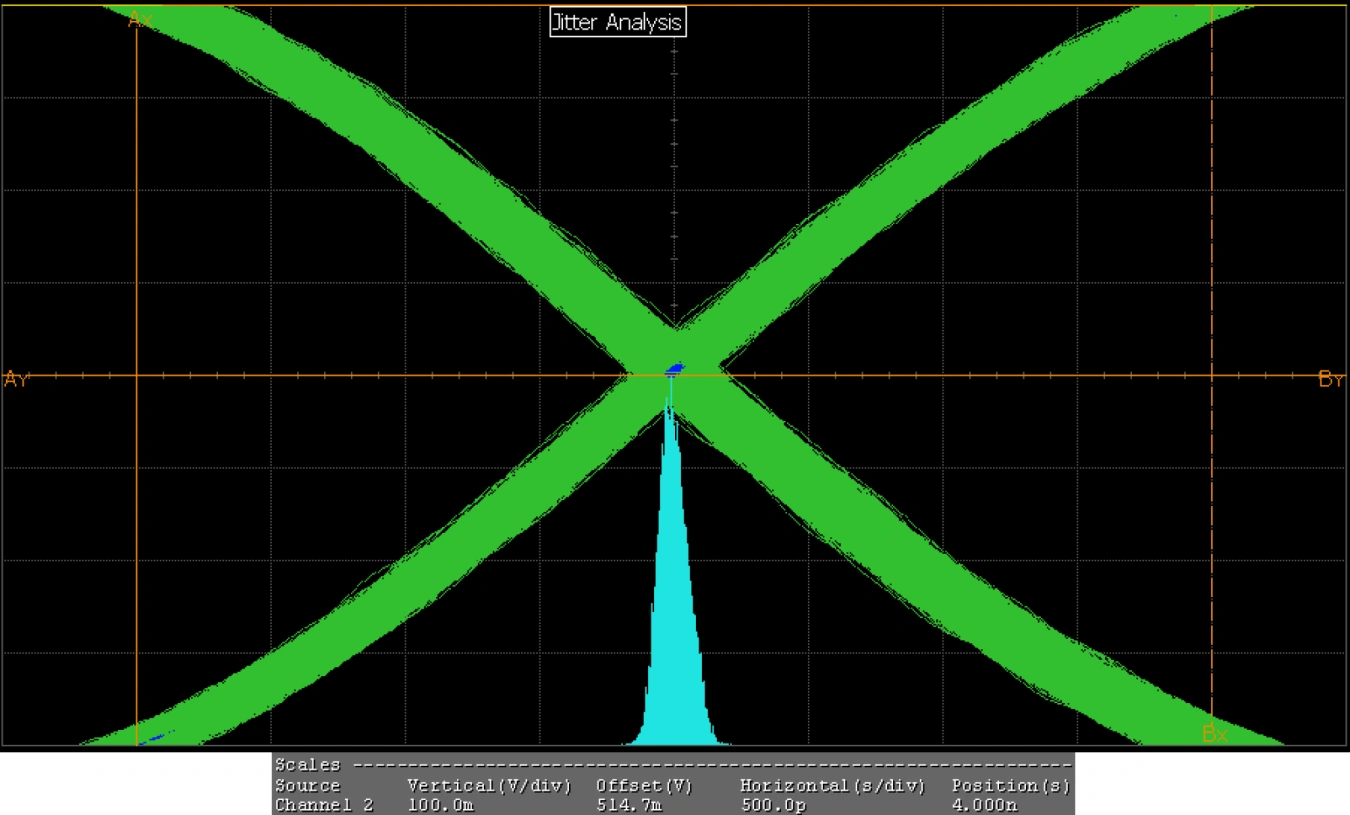

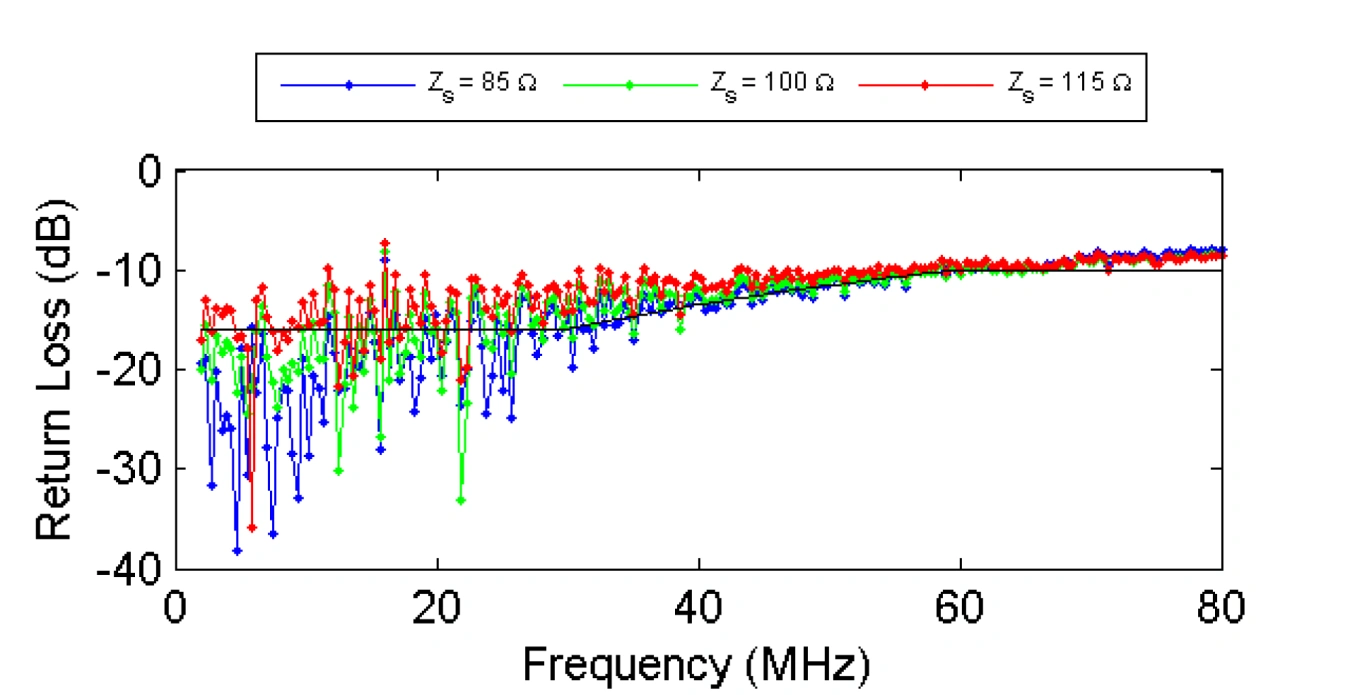

High-frequency analysis of signals and communication protocols

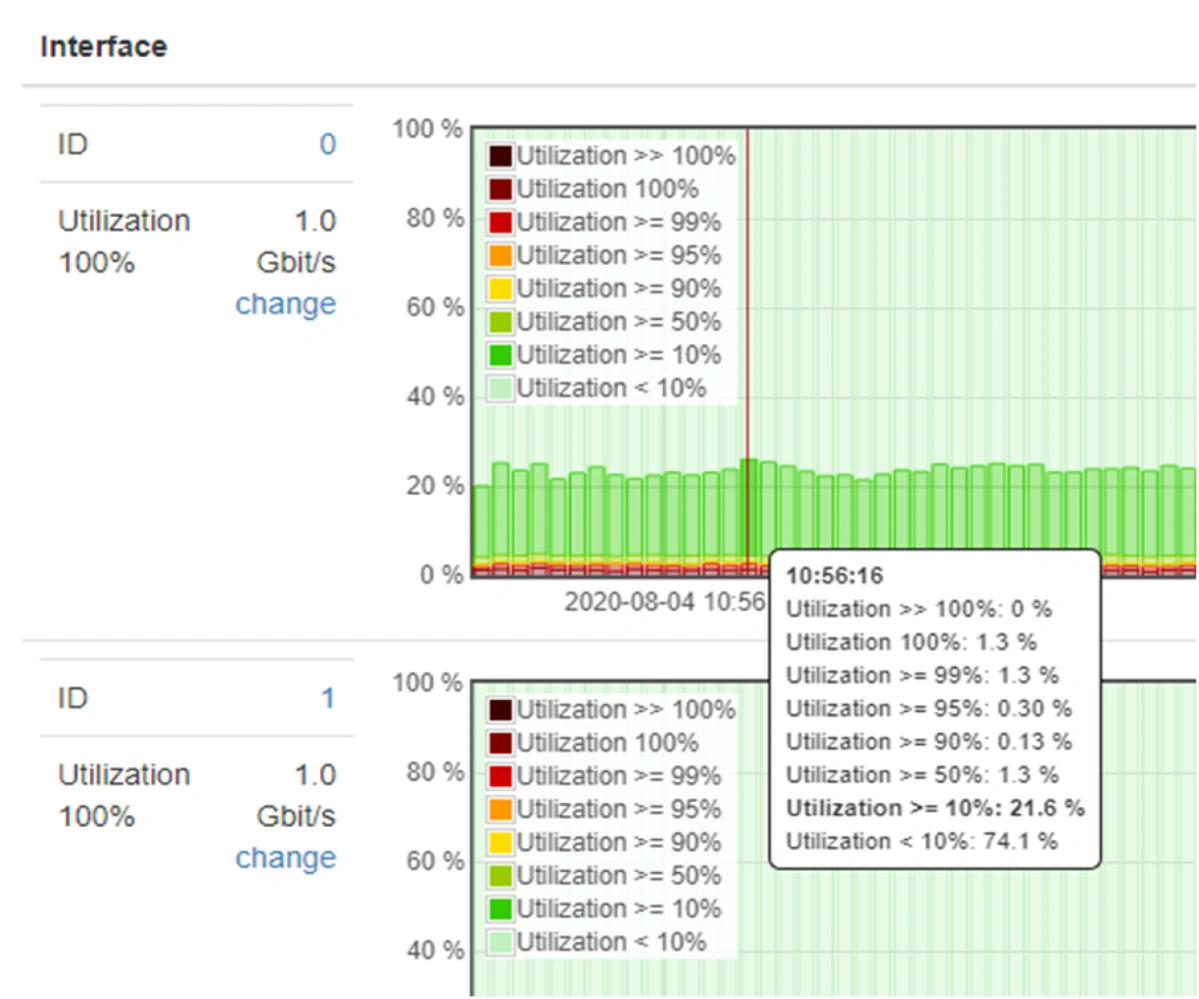

Our development teams have a wide range of testers for complex signal analysis at all layers of the OSI model.