PLC controlled heating system

Rising energy prices are increasing the pressure to replace old gas boilers with new condensing boilers with higher efficiency. However, for a truly efficient operation, it is also necessary to ensure that individual rooms are heated to the optimum temperature depending on the type of workplace and its current use. Therefore, in these applications we recommend using PLCs together with temperature measurement in all rooms with radiators and controlling the radiators with thermoelectric heads. The visualization software provides convenient management of the entire system.

|

OpenVPN - encrypted remote access |

|

LINUX - a long-term stable operating system |

| LAN - modern IP solutions | |

| COM - Modbus serial interface | |

| GSM - remote access via 2G/3G/4G-LTE | |

|

FBD & LD - graphical programming languages |

| I & O - wide range of inputs and outputs |

Application description

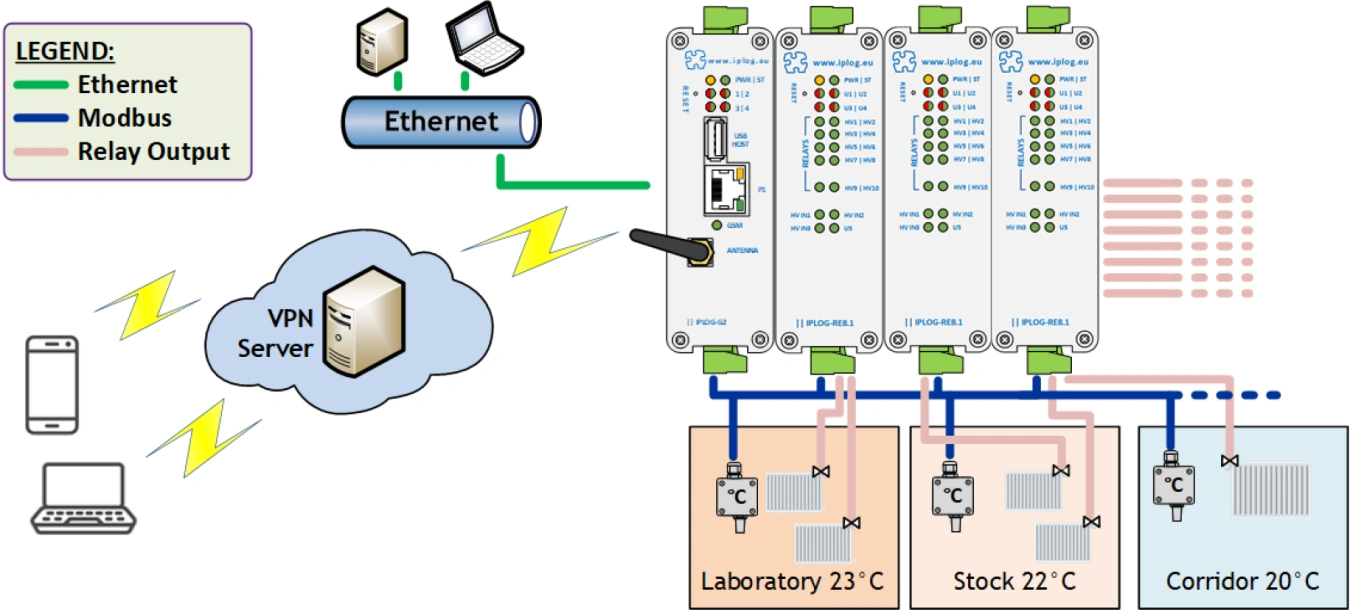

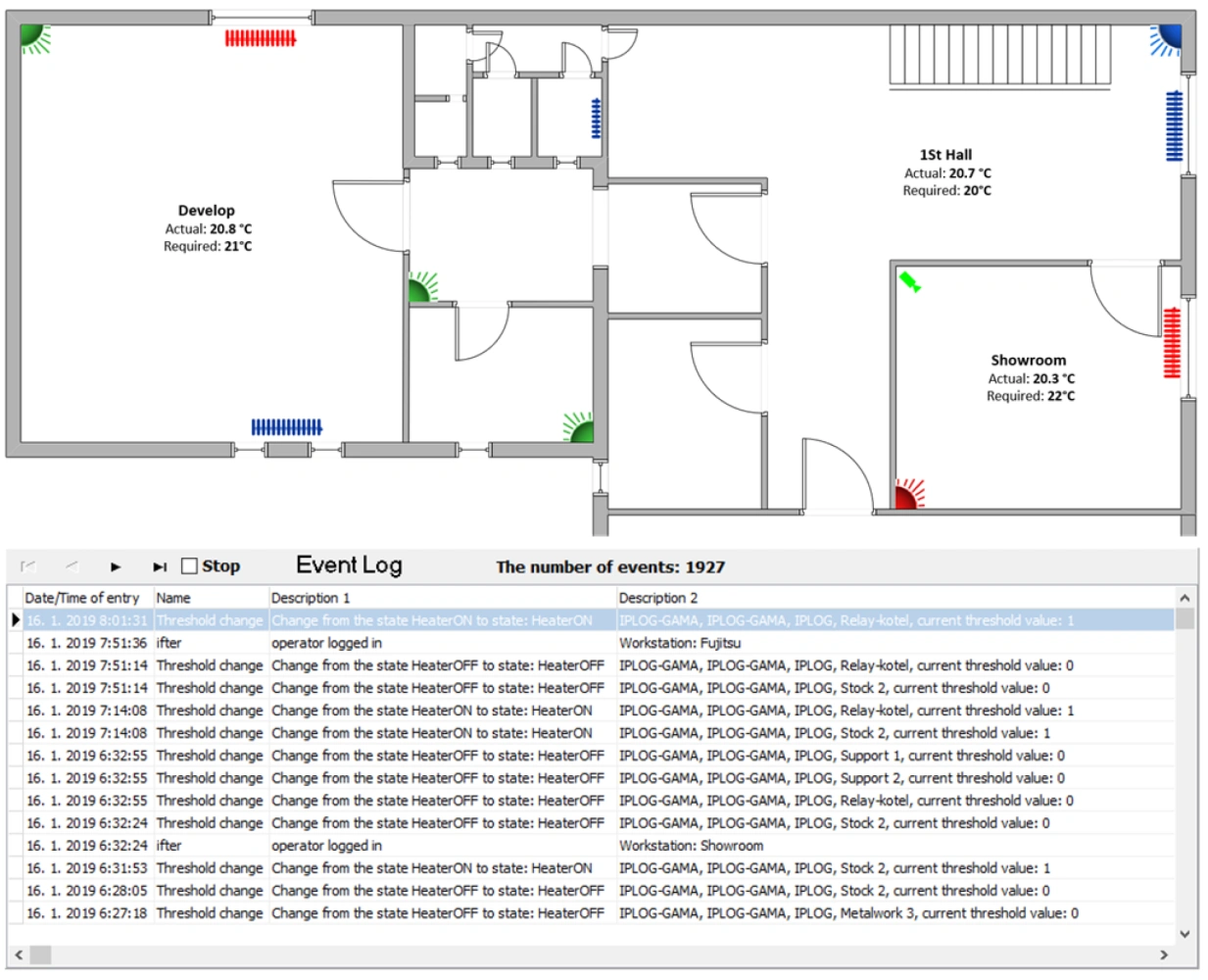

We used our own production facility to verify the correct functioning of the system and to debug it. Two outdated gas boilers and radiators fitted with thermal heads with manual controls stopped working reliably in 2017. As a replacement, we chose a Vaillant VU INT II 356/5-5 condensing boiler. After the boiler was commissioned, we prepared the hardware needed for its control:

- PLC IPLOG-G2-05 and three IO modules RE8.1-05 were installed in the central switchboard

- The radiators were fitted with thermal heads controlled by 24 VAC

- We started measuring the temperatures in all rooms with IPSEN-TH2-MOD thermometers

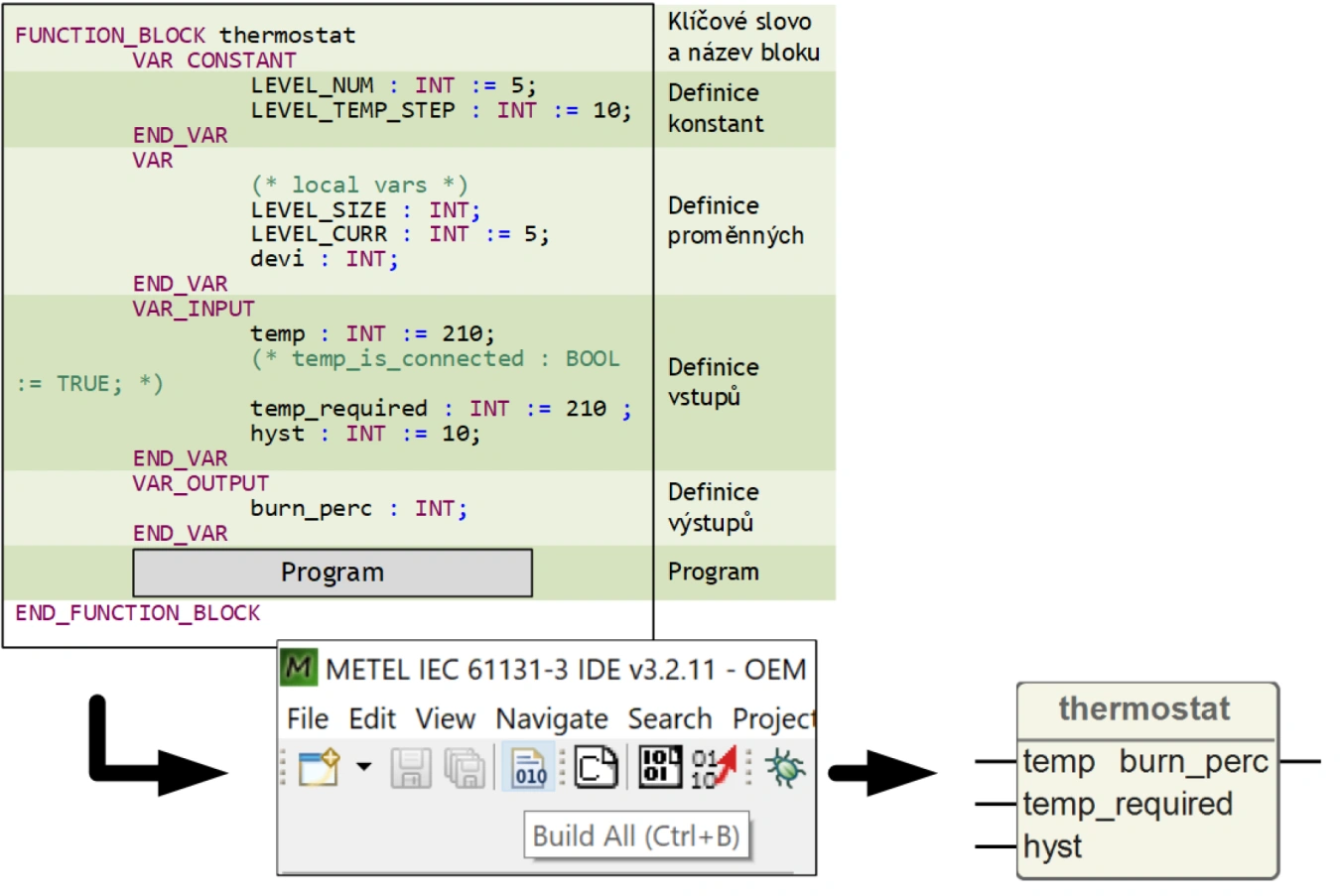

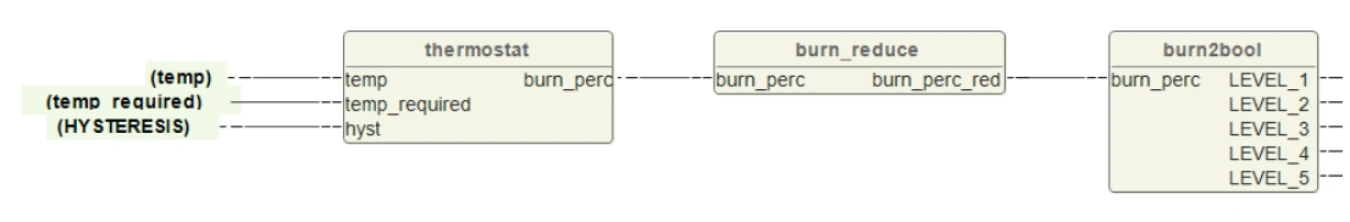

The next challenge was the programme itself. In addition, the METEL IDE programming software with hundreds of functions defined in the IEC61131-3 standard allows you to prepare custom blocks optimized for a specific job. The main reason for creating custom function blocks is also to reduce the time spent compiling a complex program from a large number of basic functions. To create a block, just insert the keyword FUNCTION_BLOCK with the desired name at the beginning of the ST language program, define constants, variables, inputs, outputs and end the program with the keyword END FUNCTION_BLOCK. Clicking on Build all then generates a function block for subsequent use in the FB graphical language. In our project, we used this procedure for example to create a thermostat function block with inputs temp (measured temperature), temp_required (target temperature), and hyst (hysteresis). Based on the current values on the inputs, the percentage output (how much to heat) is calculated.

The output of the general thermostat block is further recalculated from the percentage by the burn_reduce block. If the expected response in the form of a temperature increase in the room does not occur, the burn_reduce block performs a correction of the calculation. The result is an additional switching on of one or more radiators. The percentages calculated by the burn_reduce block are converted by the burn2bool block into the number of radiators to be heated.

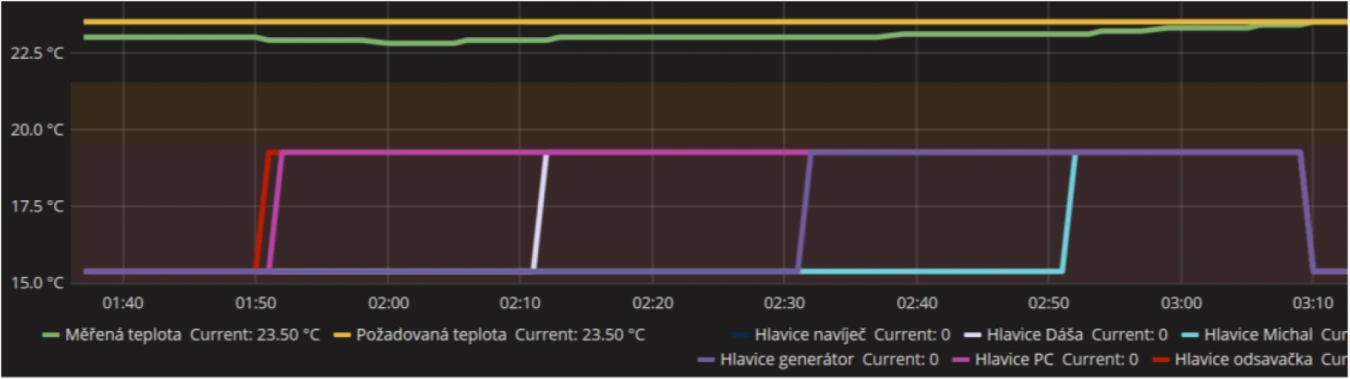

Chart with gradual switching on and off of radiators

If there is no requirement for heating by at least one radiator, the PLC automatically switches the boiler off. An outdoor equitherm sensor is also connected to the system to help regulate the boiler output depending on the outside temperature.

Other useful features

LOGGER - for any such system it is useful to know its history in addition to the current data. Therefore, all measured data is stored in a local MySQL database in the PLC and in the database of the visualization software.

WATCHDOG - the wdg.fbd block periodically writes to file 1. This writing is checked by the Linux system and in case of a program crash it restarts the program and informs the relevant persons by SMS message.

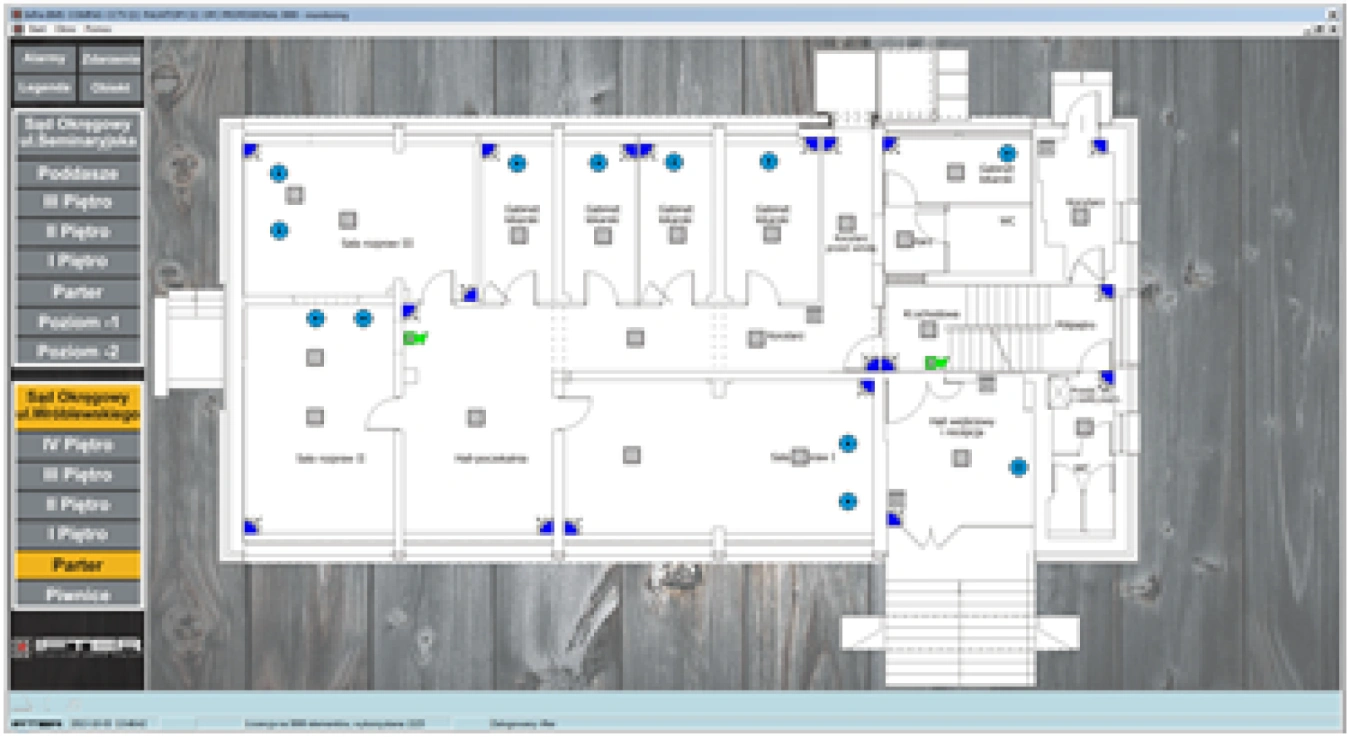

HARMONOGRAMS AND VISUALIZATION - The IFTER-EQU visualization software is used to visualize the entire system and set schedules that determine when to heat to day temperature and when to night temperature (the room is not used).

Conclusion

The PLC controlled heating system has helped to significantly reduce heating costs. Each room is heated only to the optimum temperature. If it is not being used, the temperature is automatically reduced, further increasing the cost savings. The built-in GSM router provides remote online monitoring and informs about emergency situations via SMS messages.

Ordering information

| NAME AND CODE | DESCRIPTION | |

|

IPLOG-G2-05* 5607-0000 |

PLC unit with 2G / 3G modem, RS485 Modbus RTU for connecting external IO modules and sensors, 2x alarm / 5V digital inputs. * You can configure PLC with other inputs, outputs and serial interfaces in online configurator http://www.metel.eu/iplog-configurator. |

|

RE8.1-05-BOX 5000-0507 |

IO module: 8x NO 230V relay outputs, 3x optically isolated 230V inputs, 2x NOC 230V relay outputs, 1x RS485 Modbus port, 2x 5V alarm/digital inputs, operating temperature -40°C to +70°C, integrated surge protection 600W |

|

IPSEN-TH2-MOD 5-202-283 |

RS485 Modbus-RTU temperature/humidity sensor, operating temperature: -40°C to +80°C, relative humidity: 0-100% RH, accuracy: ± 0.4 °C / 3% RH (25°C) , 12VDC |

| EQUIPMENT FROM OTHER MANUFACTURERS | |

| Thermocouples 24V | Visualization software IFTER-EQU |

|

|