Management and protection of water resources

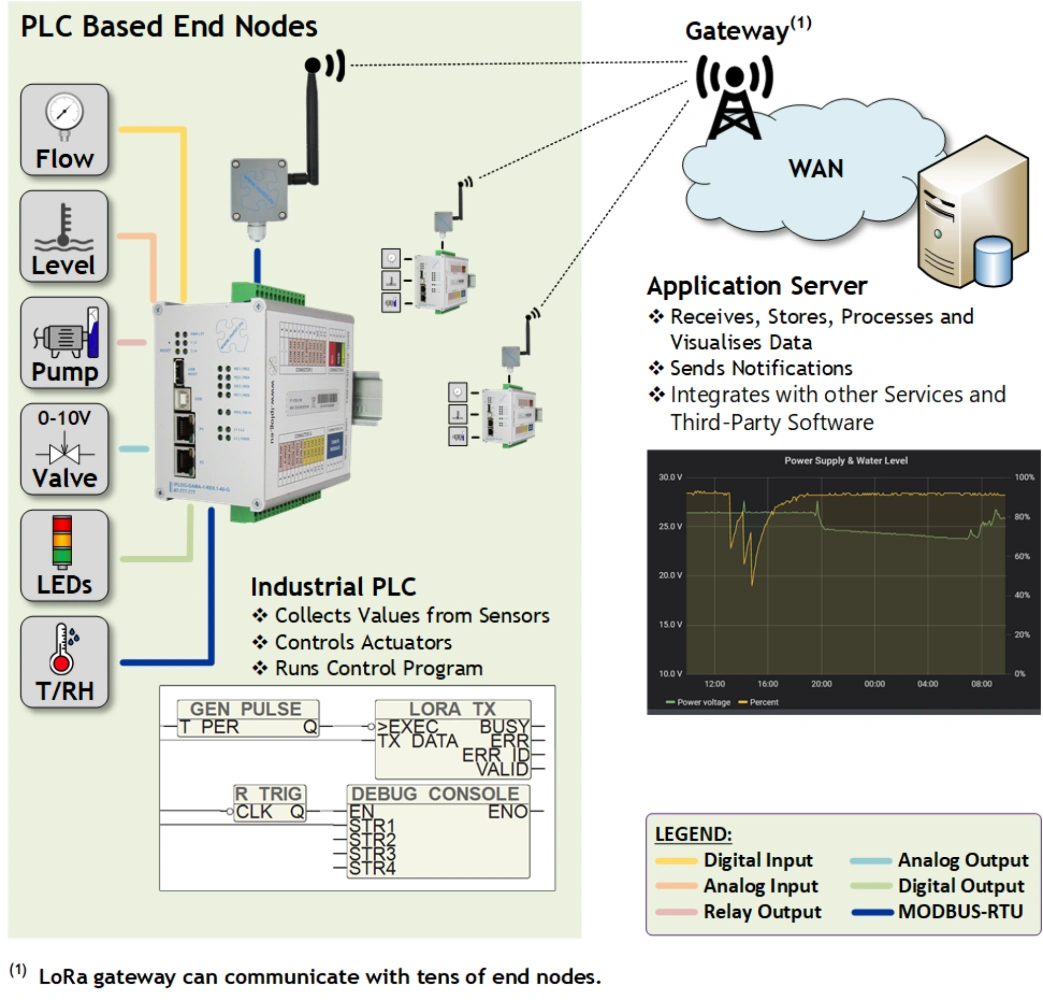

The LoRaWAN wireless standard is the ideal solution for monitoring and managing remote water resources. In addition, our LoRaWAN PLCs are significantly more flexible than conventional endpoints measuring 1-2 variables. The modularity of the PLC allows you to build an endpoint with dozens of different inputs and outputs. In addition, the endpoint can independently run its own control program written in EN61131-3 programming languages.

- Wireless & Encrypted Network

- PLC-based endpoints

- Large selection of inputs and outputs

- Suitable for OFF GRID applications

Wireless & Encrypted Network

LoRaWAN combines low data rates and robust modulation to achieve a communication range of units of km. The key advantages of LoRaWAN technology are bidirectional communication and long range, which is typically 2-5 km in urban areas and 15 km in suburban areas. All LoRaWAN devices encrypt the transmitted data using the AES algorithm with a key length of 128 bits.

PLC-based endpoints

LoRaWAN devices have a "duty cycle" limitation of 1%, which does not allow real-time communication and especially real-time remote control. Our endpoints based on IPLOG-GAMA modular PLCs largely eliminate this shortcoming. The PLC runs the control program independently of the central server and only the necessary data for visualization, logging and operator feedback is transmitted via the LoRaWAN. Typical application examples are alarm systems for monitoring remote areas, collecting data from weather stations, controlling water pumping from wells, etc.

Large selection of inputs and outputs

With modular PLC-based endpoints, a wide range of inputs, outputs and serial interfaces can be used. Each endpoint can thus contain up to dozens of inputs and outputs and function as an IO concentrator with LoRa interface. In addition, sensors and IO modules with LAN, 1-Wire or Modbus interfaces can be connected to the PLC.

DEMO OFF-GRID System

All interested parties are invited to visit our DEMO system in Ceska Skalica. The system practically demonstrates a solar pump with remote control and monitoring via LoRaWAN wireless network.

March 2017

The creation of the DEMO system itself was preceded by an exploratory borehole 50 meters deep.

2017 - 2018

After the completion of the borehole, we continued with the construction of the canopy and not very successful tests of the pump driven by a 12V electric motor. The pump was not efficient and reliable enough for the water level of around 33m.

May 2019

We have completed the development of the IoT LoRaWAN interface for our IPLOG PLC.

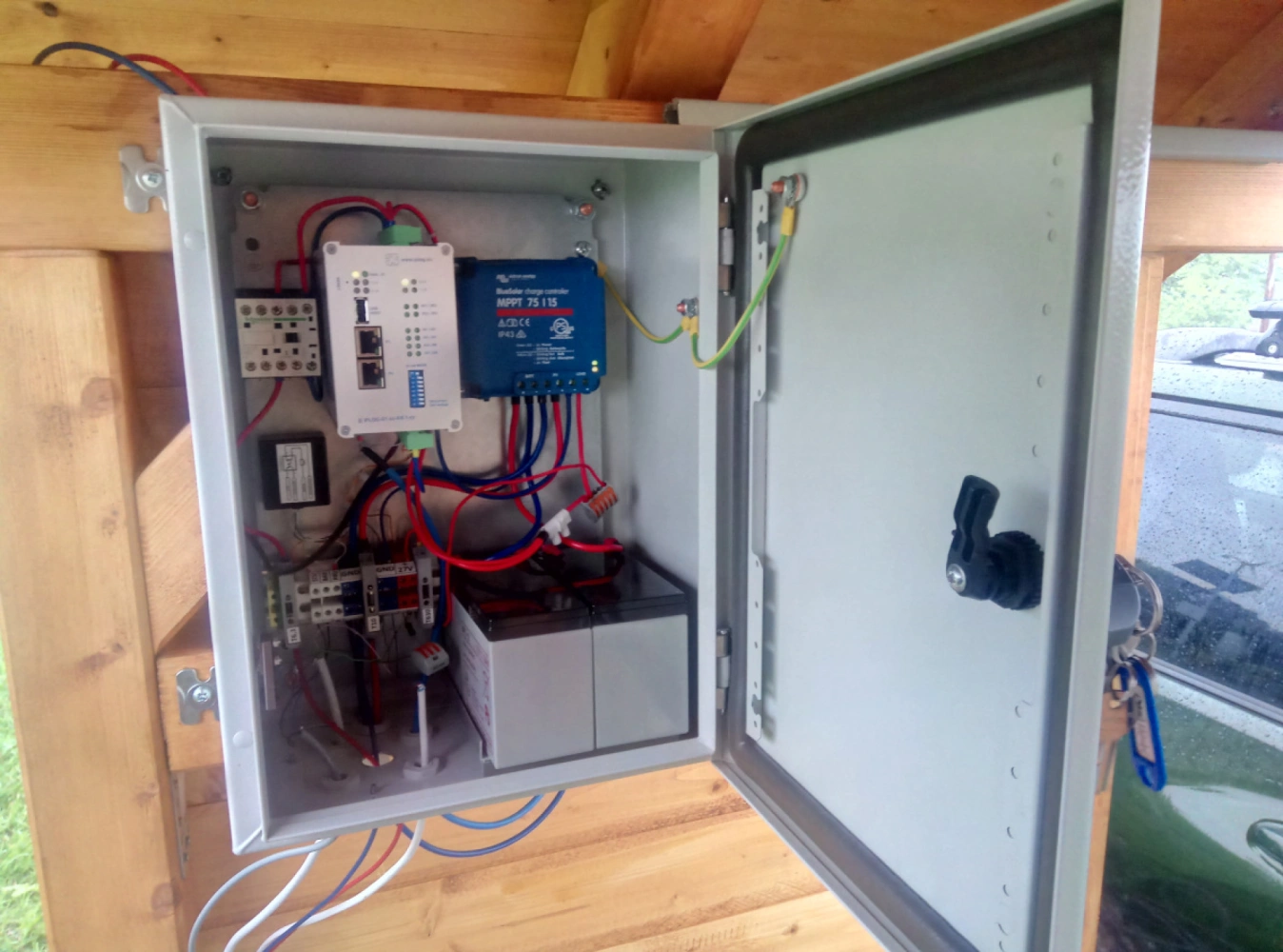

To thoroughly test the functionality in OFF-GRID mode, we installed the following on the well:

Solar panels

LoRaWAN End Node

PLC IPLOG-GAMA with charger

24 VDC submersible pump